The modular transfer system for your plant

Low maintenance and reliable transfer system

Intuitively configurable transport system

Durable for optimal transfer of the workpiece carriers

Precise circulation system

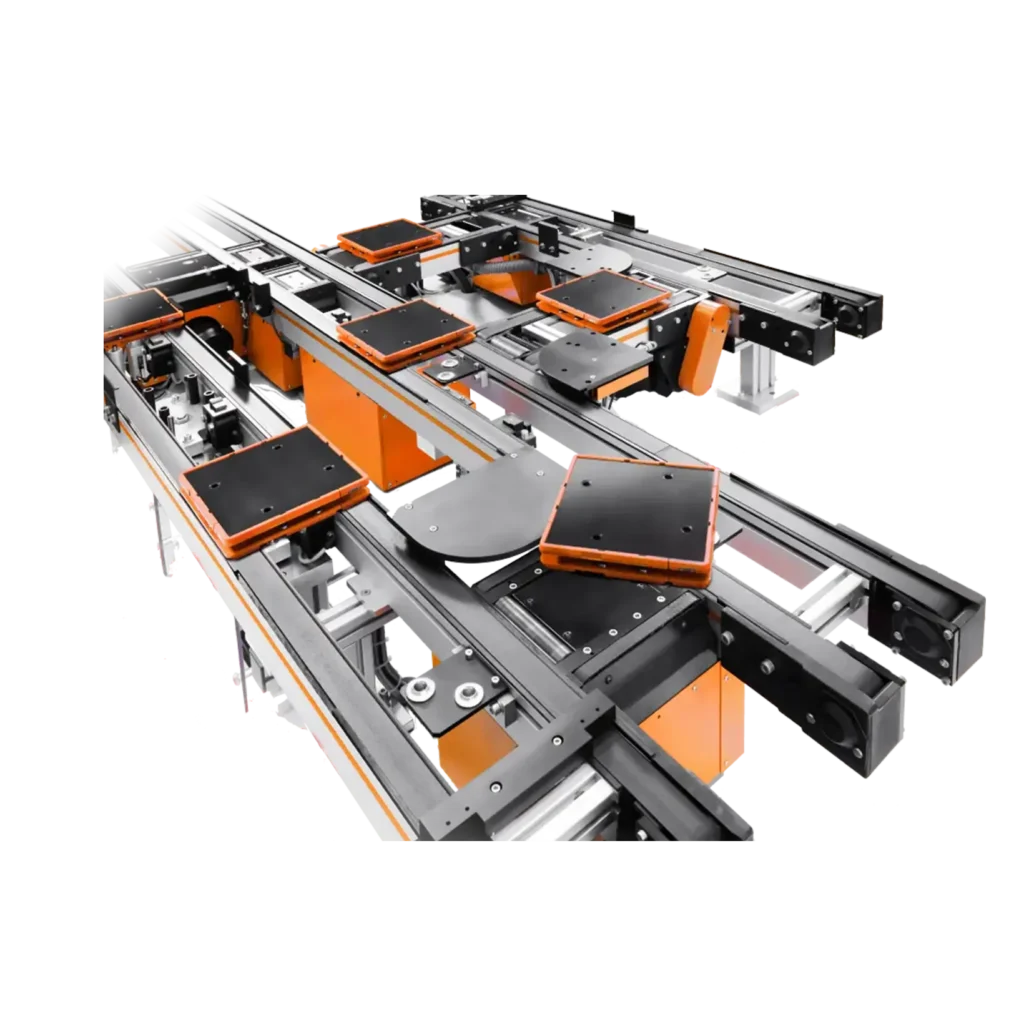

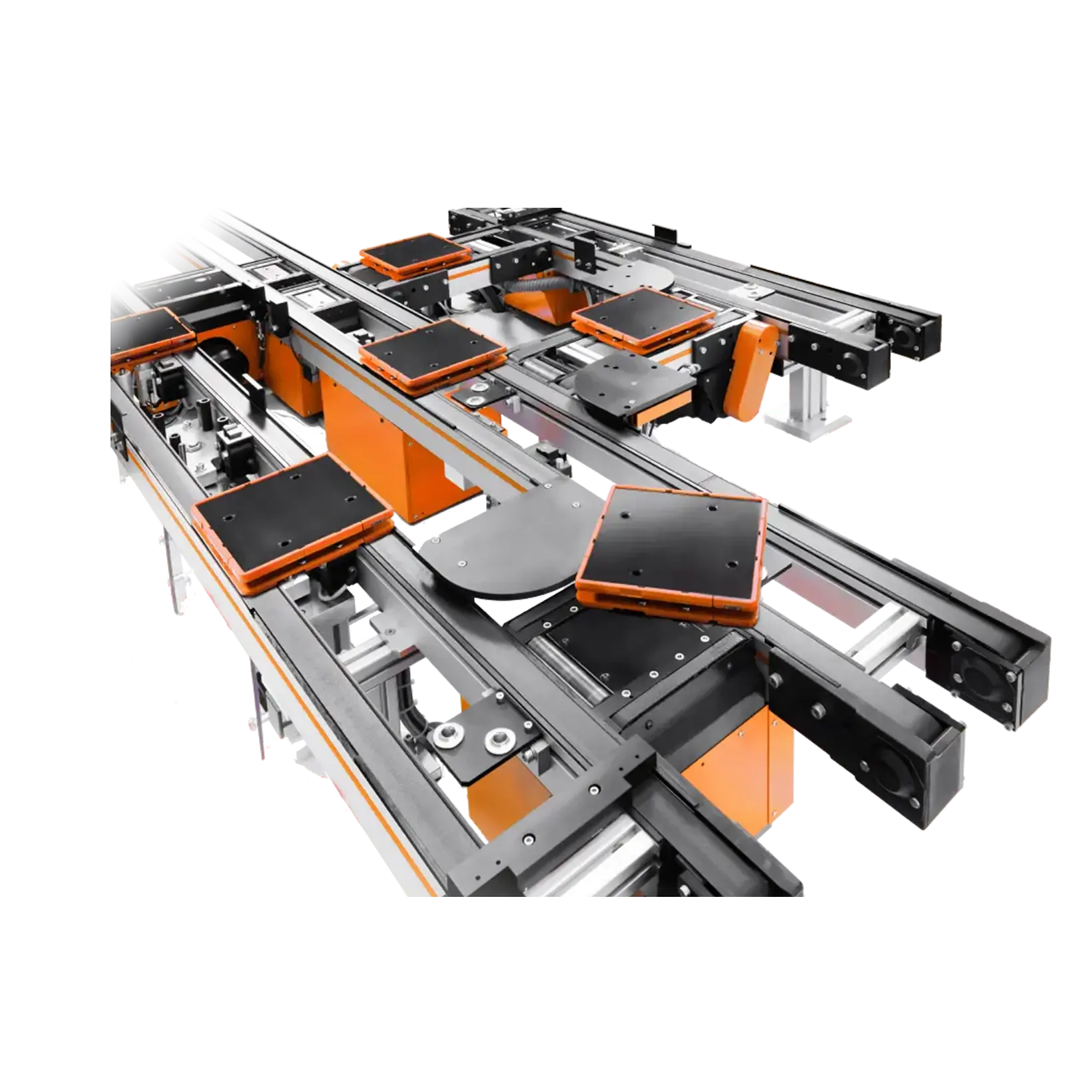

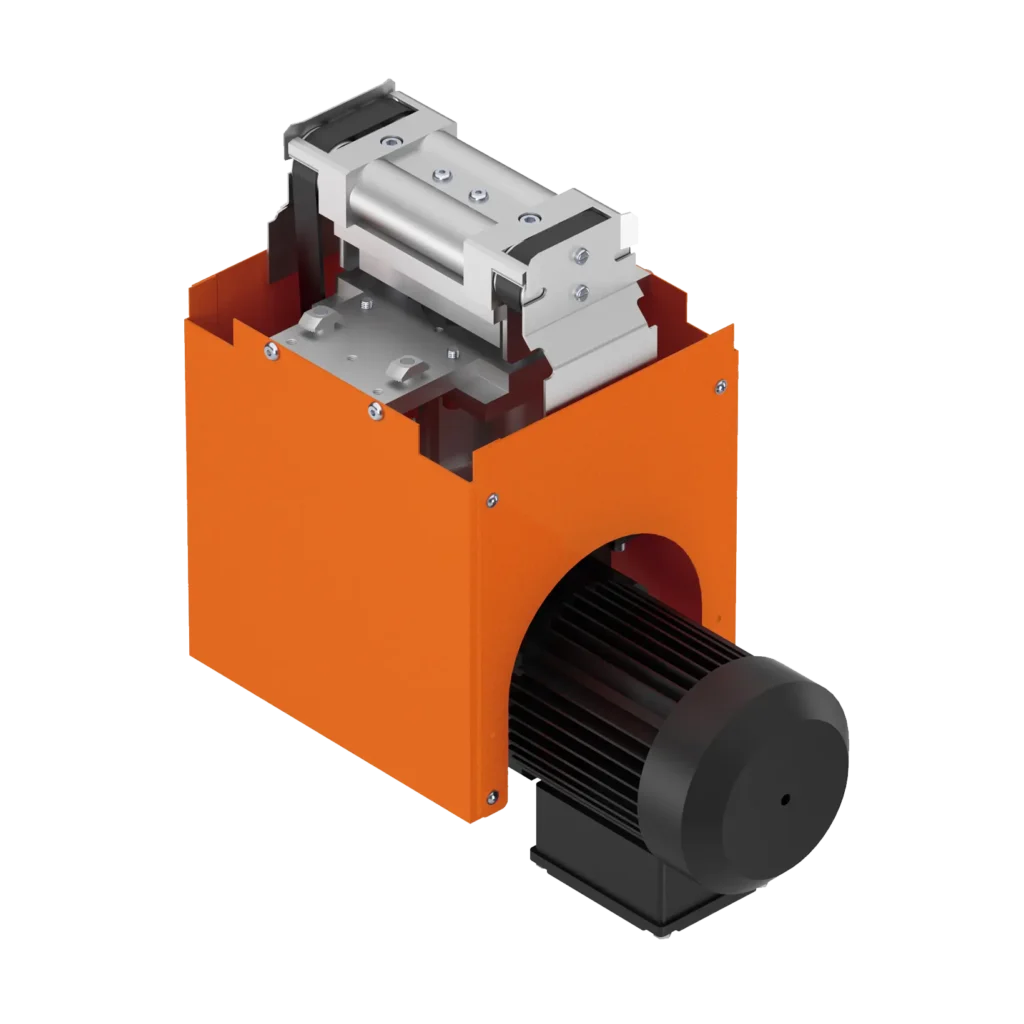

The Linear Transfer System – LTS for short – represents a transport system which is suitable for all common assembly and joining operations and any machining from above as well as from below. Extensions with automatic stations on the longitudinal and transverse lanes can be implemented without any problems. The linear conveyor system can also be supplemented with cycle-independent workstations if required.

For cycle time-critical operations, id: MOTION’s linear transfer system enables parallel path designs and variants on different levels. Individual machining of the workpieces on the workpiece carriers by means of deflectors and lifting elements is also conceivable.

Due to our modular system we can guarantee short delivery times as well as an excellent price-performance ratio.

Feel free to contact us if you have a question or need more information.

Long service life and safety in the production process characterize the Linear Transfer System

Conveyor system with maximum user and changeover flexibility in plant configuration

Freely available CAD drawing for optimal integration of the Linear Transfer System in customer projects

Our linear workpiece carrier systems are easy to assemble and put into operation because they are already pre-assembled.

id: MOTION offers proven transfer systems for economical transport solutions that can be scaled to meet the needs of almost any application. Regardless of whether it is a matter of fully or partially automated systems with high quantities or small batch sizes of the most varied designs – all systems are modular in design. This enables fast planning and easy expansion or retrofitting of existing plants.

The id: MOTION Linear Transfer System is constructed from an optimally matched modular system of standardized individual components. This means that practically any plant layout can be implemented.

Transport lines are available in 5 different lengths and 3 transport speeds. Transport tracks with a maximum length of 6 meters are made of only one track profile and can be delivered completely pre-assembled.

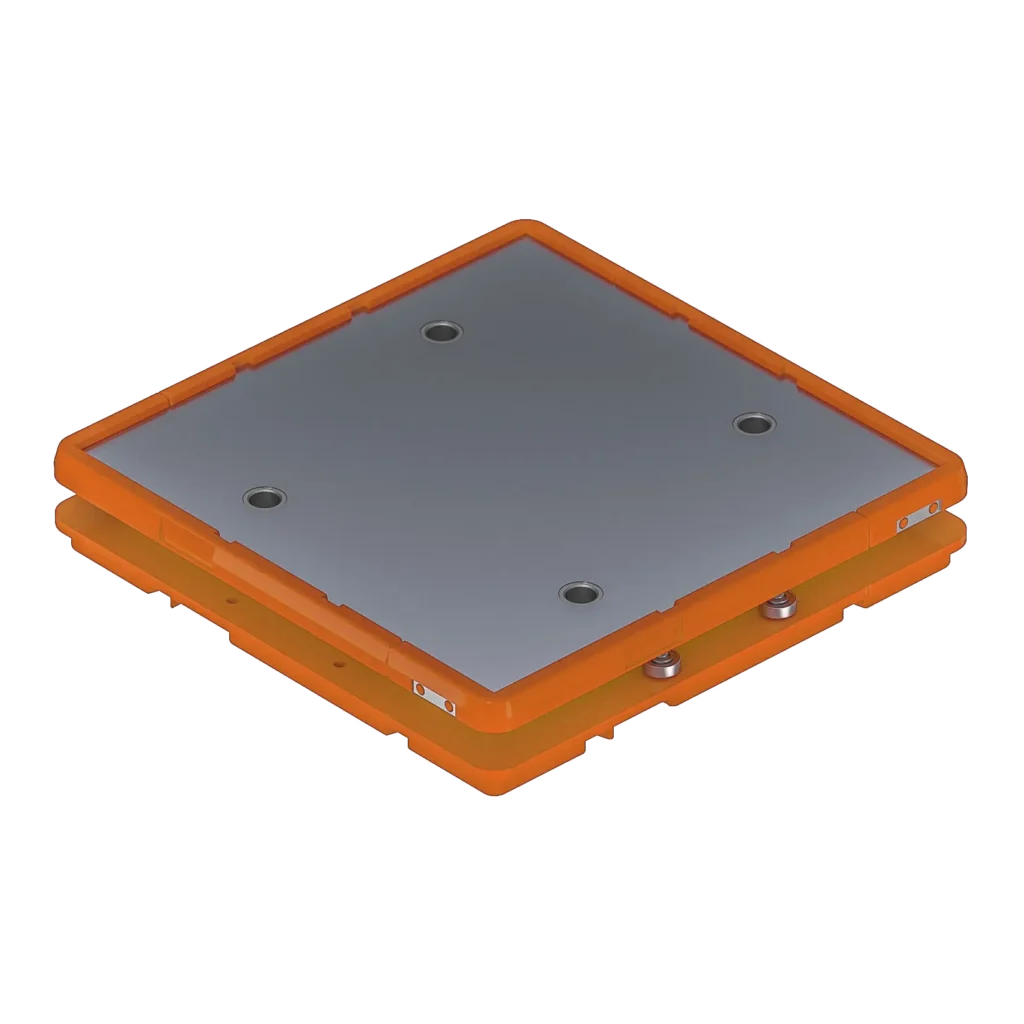

Workpiece carriers in sizes 160, 200, 250, 320 and 400 mm can be combined to form 13 standard variants. Support plates made of steel or aluminum. Maximum weight per workpiece carrier up to 20 kg.

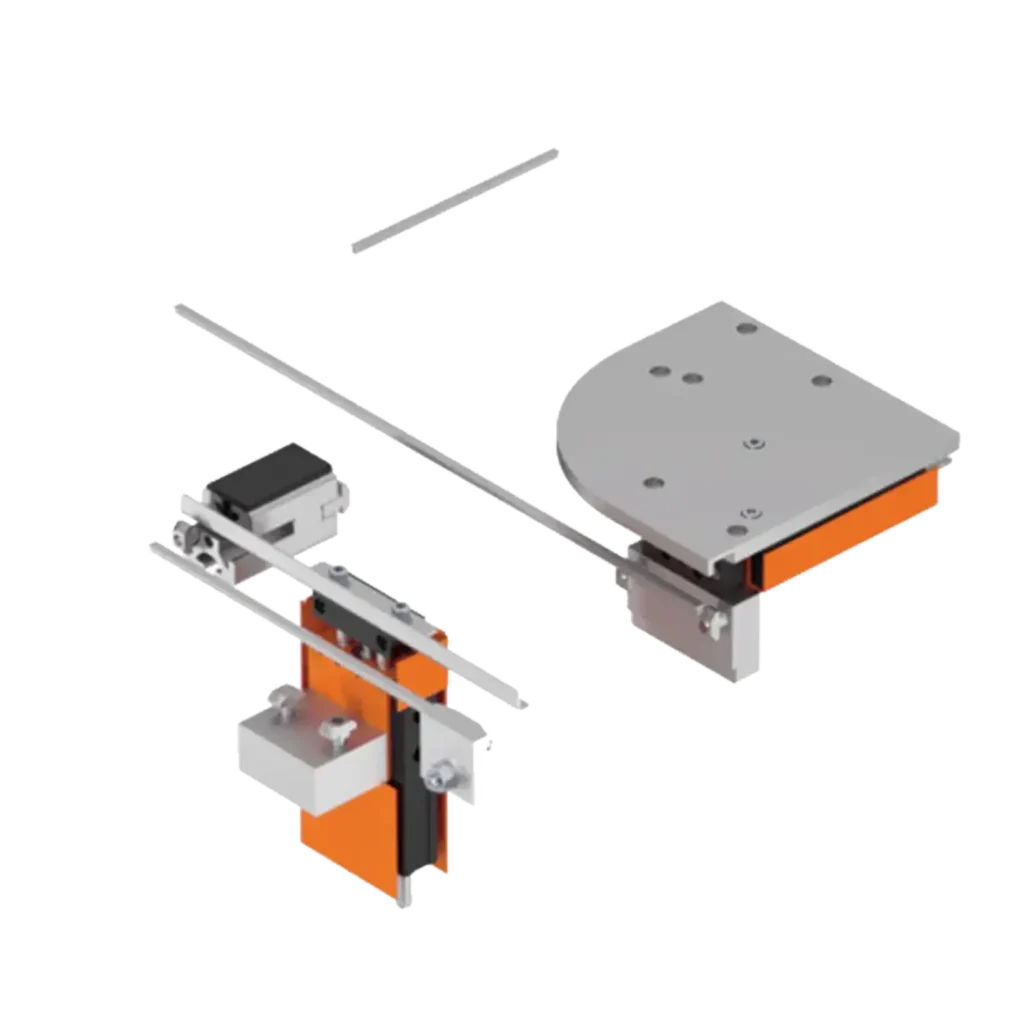

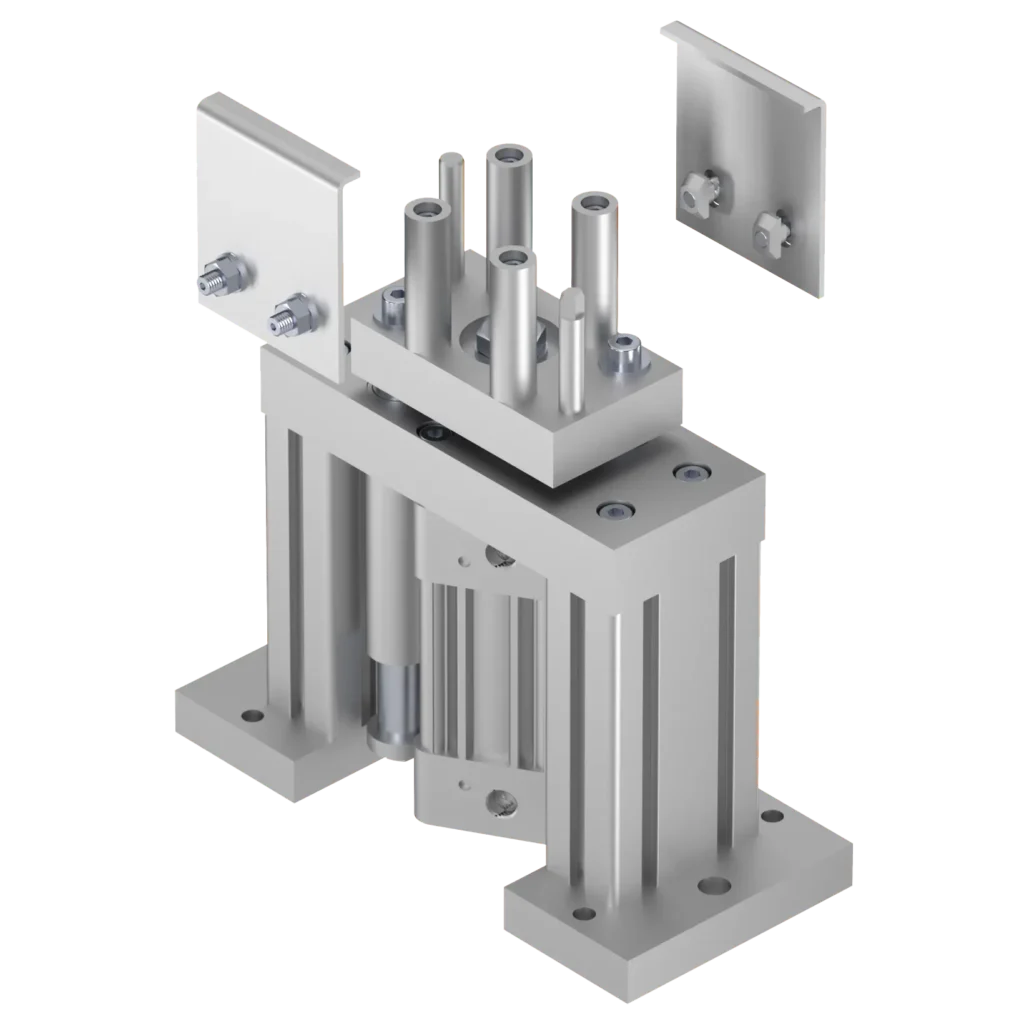

By means of the deflection guide (fixed or movable), a directionally constant, vibration-free transport of the workpiece carriers is possible, both at the end of the belt and with the switch function for by-pass sections.

The infeed/outfeed lifting element HE is used where workpiece carriers have to be discharged from a longitudinal track into a transverse track or fed from a transverse track into a longitudinal track.

Suitable equipment for positioning the workpiece carriers is available for all common assembly and joining operations, including machining from below.