id:MOTION

Linear Transport Module

A fast-cycle transport module for linear transport of workpieces

Compact design

Speed

Flexibility

Precision

LTM

Flexible modular system

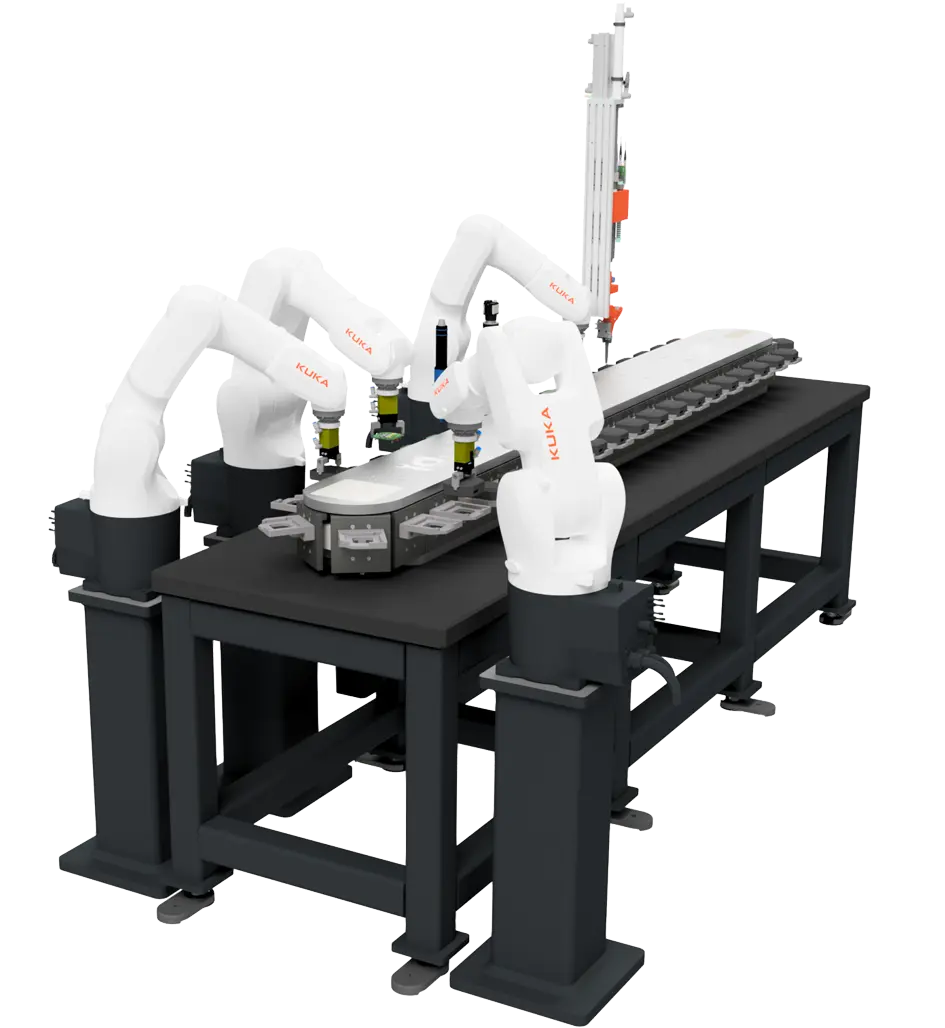

The Linear Transport Module – LTM for short – is a fast-cycle transport module with fixed workpiece carrier plates. The id:MOTION transport system enables a high machine output depending on the requirements of the attached work stations . The time required for the linear transport of the workpiece carriers is reduced to a minimum. The Linear Transport Module can be used as a stand-alone linear indexing system or in combination with an assembly system – as with a rotary indexing table.

Transport systems

Linear Transport Module

as a linearmontage system

-

Very short changeover times of the workpiece carrier in the transport system, so that the feed time is reduced to a minimum.

-

Flexible cycle step lengths due to the built-in servo drive in the transport module.

-

Type changeover at the push of a button, so that the user does not have to make any mechanical conversions.

-

High precision for efficient repeatability.

-

Flexible sizes due to two types of workpiece carriers with different widths.

-

Good accessibility due to the linear arrangement of the stations within the linear assembly system.

-

Slim design due to the small footprint of the Linear Transport Module.

-

Open motor interfaces to be able to install common drives according to customer requirements.

-

Short delivery times of the Linear Transport Module (12 weeks from receipt of order).

-

No fixed running direction of the linear transport, the transport modules can also be operated backwards.

-

Customized machining

Transport

Individual transport solutions with id: MOTION transfer systems

id: MOTION offers proven transfer systems for economical transport solutions that can be scaled to meet the needs of almost any application. Regardless of whether it is a matter of fully or partially automated systems with high quantities or small batch sizes of the most varied designs – all systems are modular in design. This enables fast planning and easy expansion or retrofitting of existing plants.

Transport systems

Our two systems

Linear Transport Modul vertikal (LTM-V)

The LTM-V is a fast-cycle linear transport module that allows high machine outputs depending on the design of the pick and place stations. The time for workpiece carrier transport is reduced to a few tenths of a second.

This gives you more process time for the actual application.

The dimensions of the linear transport module depend on the assembly parts to be transported. In addition to the working length, these also determine the width of the workpiece carriers.

The LTM-V is characterized by flexible feed lengths, high payloads, two standard widths of the workpiece carriers and a very good price-performance ratio

-

Extremely short feed time (up to 180 cycles/min)

-

Flexible feed lengths

-

Product changeover at the push of a button, without mechanical adjustment

-

Repeatability up to ± 0.1 mm in running direction

-

Flexible sizes

Linear Transport Modul horizontal (LTM-H)

Your alternative to the rotary indexing table!

With possible machining of the workpiece carriers from above, below and laterally, the Linear Transport Module offers several advantages horizontally.

The horizontal design allows the operator to occupy all workpiece carriers in a circumferential manner and thus offers very efficient use of space. The narrow design leaves, on or next to the module, enough space for the required workstations. The wide range of attachment options allows workpieces to be machined horizontally, vertically, laterally and at the front. As with our proven horizontal variant, the LTM-V, various sizes are also available for the LTM-H thanks to its modular design.

Due to the robust construction, the belt drive and the high repeatability, you get with our Linear Transport Module LTM-H a durable and almost maintenance-free product. All without high installation costs or any periodic maintenance!

-

Machining of the workpiece carriers possible from above, below and laterally

-

Very good price performance ratio

-

High process density possible with low space requirement

-

Repeatability up to ± 0.05 mm

-

Very good accessibility to the stations

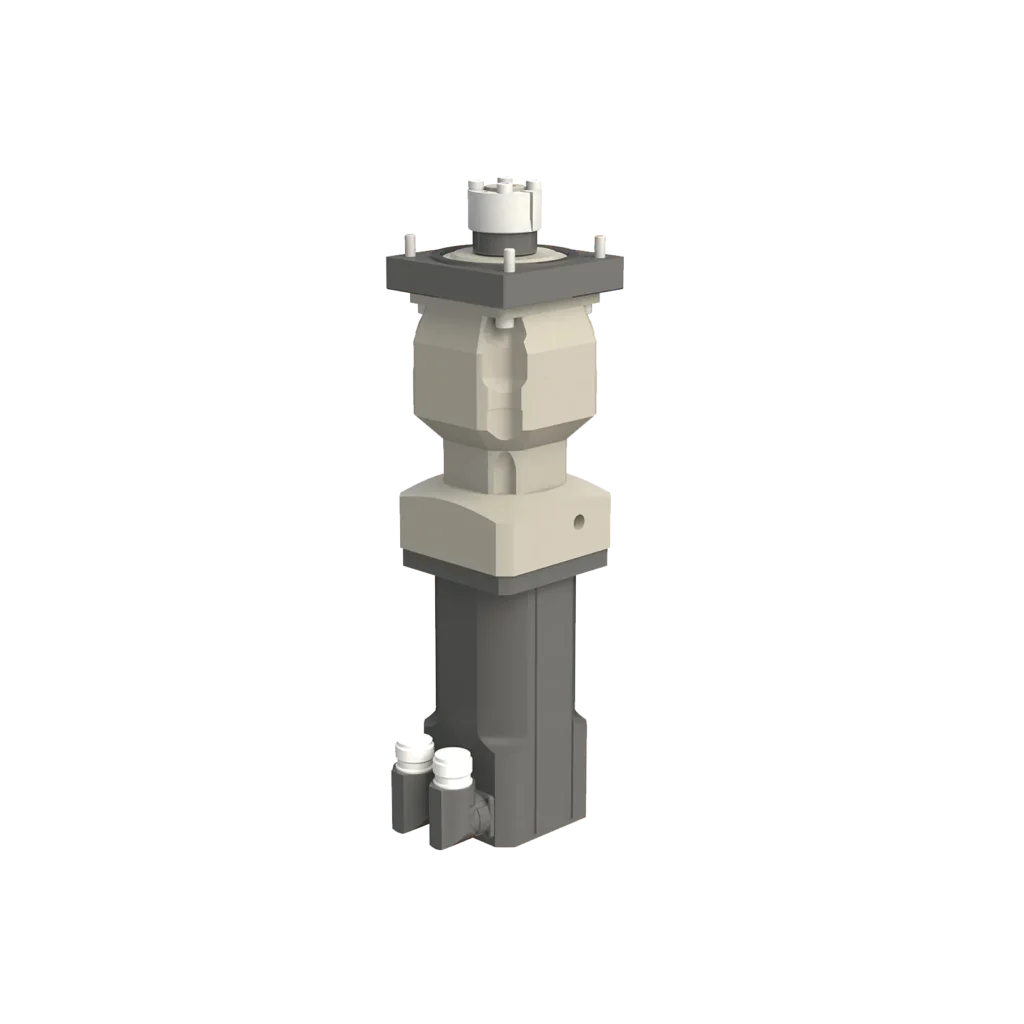

Configuration

We configure and assemble the LTM-H for you from the following components:

Modules

The LTM-H linear transport module is built up from the following modules:

- 1 x drive module

- 1 x deflection module

- Up to 5 center modules

The required working length determines the number of center modules to be installed per LTM-H. Depending on the number of center modules, the working length is between 720 and 3720 millimeters.

Drive package

Consists of these components:

- Attachment set

- Planetary gear

- Servo motor

- ID: Motion SE Power Servocontroller

Controller

- Easy programming via PC, USB or RS-232 interface

- Factory parameterization and commissioning

- Commissioning within minutes

- 250 positions

- Control via digital inputs/outputs, Profi-Bus, CAN-Bus, EtherCAT